|

Molgas and NorSea Logistics reopen LNG facility in Kristiansund

The reopened facility will supply LNG and bio-LNG to dual-fuel vessels operating in Norwegian waters. |

|

|

|

||

|

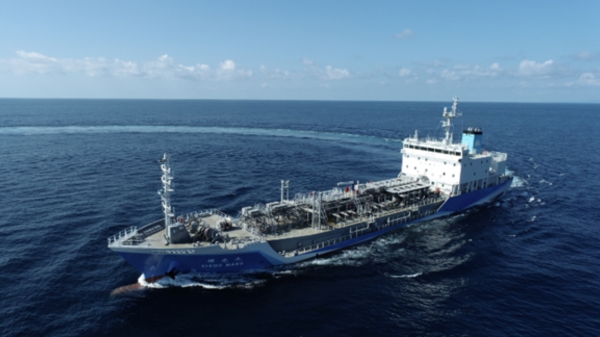

Hydrogen-fuelled tanker achieves top rating in zero-emission programme

Kikou Maru becomes first coastal vessel to secure financing under DBJ-ClassNK decarbonisation initiative. |

|

|

|

||

|

TFG Marine calls for ISO 22192 alignment in ARA MFM rollout

Company urges consistency as Rotterdam and Antwerp prepare mass flow meter implementation. |

|

|

|

||

|

Peninsula renews $400m Singapore credit facility as part of $1.5bn funding capacity

Bunker supplier extends banking arrangement with eight-bank syndicate, including accordion option. |

|

|

|

||

|

Titan delivers first liquefied biomethane to Saint-Malo ferry in Portsmouth

Optimus tanker supplies Brittany Ferries' vessel with biomethane at UK port. |

|

|

|

||

|

MOL outlines ammonia fuel strategy at Houston conference

Japanese shipping company discusses terminal acquisition and dual-fuel vessel plans at industry gathering. |

|

|

|

||

|

Gasum highlights how bio-LNG fleet generates compliance surplus

Energy firm's four gas-powered vessels generate regulatory surplus for pooling service participants. |

|

|

|

||

|

Monjasa secures NATO fuel supply contract across five operational areas

Danish marine fuel supplier wins one-year framework deal with two-year extension option. |

|

|

|

||

|

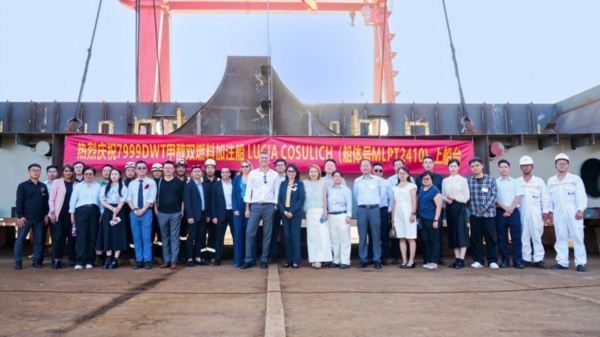

Fratelli Cosulich lays keel for second methanol-ready bunker vessel

Ceremony held to mark the beginning of the tanker's assembly phase. |

|

|

|

||

|

GEFO bunkers biofuel for first time as Gioconda runs on B100 UCOME

German shipping company takes maiden step into biofuel bunkering with used cooking oil biodiesel. |

|

|

|

||

| Technology to eliminate particulate emissions from ships [News & Insights] |

| Scrubber 'successfully' tested on board Maersk ship [News & Insights] |

| ECSA calls for global agreement on emissions reduction [News & Insights] |

| Bulk carrier installs SOx scrubber monitor [News & Insights] |

| Emission systems for cleaner and greener ships [News & Insights] |