Det Norske Veritas (DNV) has urged the shipping industry to be more proactive in their efforts to reduce fuel consumption. In addition to missing out on significant savings opportunities, DNV claims the industry is failing to take advantage of proven systems and routines which will help the industry reduce carbon emissions.

According to an IMO study released earlier this year, annual carbon dioxide emissions released by the global merchant fleet reached 1.12 billion tonnes in 2007, making up about 3.5 percent of total global carbon emissions. Yet a large number of shipowners appear to have continued to operate as normal, despite the looming threat of new IMO legislation on carbon emissions and a corresponding steep rise in the cost of fuel.

According to Dr.

Espen Cramer [pictured], head of

DNV Maritime Solutions, shipowners have long recognised the business value of reducing fuel consumption, but many have failed to implement more effective and comprehensive energy management strategies.

“The industry’s piecemeal approach to reducing fuel consumption has slowed the efforts of shipowners to make a real difference,” he said.

“Most companies have not allocated internal resources to optimise fuel consumption, lack clear goals and ambitions, fail to communicate their efforts effectively, do not benchmark and report fuel reduction obtained, and many simply outsource the problem to ship managers rather than work with them,” added Cramer.

In 2005, DNV launched its

Energy Management service, which it says provides a systematic approach to enable shipping companies to reduce annual expenditure related to fuel and improve their environmental footprint.

This is said to be achieved through improvement identification, solution development for prioritised areas, followed by implementation and monitoring of improved performance. DNV says the implementation of Energy Management also facilitates clear documentation of improved environmental performance, which can deliver a competitive advantage.

“We have identified a fuel saving potential of between five and twenty percent for ships in operation, depending on present performance of the company,” said Cramer. “Yet, the implementation to actually realise this saving potential remains a challenge for many shipowners and ship managers.”

Through three years of experience with Energy Management, DNV claims that it has collected a number of examples of companies which have limited or no knowledge of how effective they are in energy consumption, have no comparison of consumption of individual vessels in their own fleet, or fail to benchmark their progress.

“We also see that many companies start with expensive, costly solutions without first identifying and implementing more cost-effective quick-win solutions.” commented Cramer.

To date, DNV says that it has conducted some 20 fuel efficiency projects where it has helped companies move forward with fuel savings by taking into account both organisational and technological solutions.

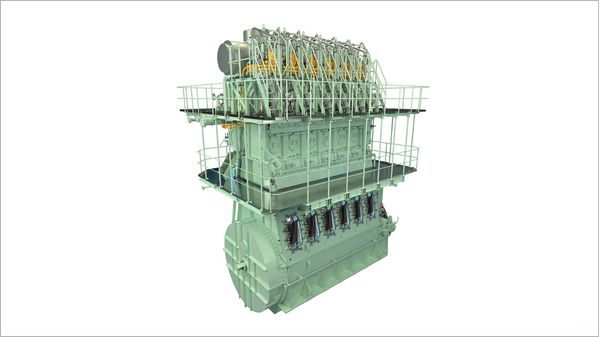

DNV has grouped the areas where companies can save fuel into six; -Voyage Performance, which includes optimising voyage planning and weather routing, -Ship Performance, which includes the condition of the hull and propeller and optimising trim and draft, -Bunker Management, which focuses on fuel procurement and management, -Main and Auxiliary engine tuning and optimisation, -Energy Consumers, which includes tank cleaning, thrusters operations, incinerators, and ventilation and HVAC, and -Management & Organisation, which focuses on policy performance management, training and awareness, and following through on environmental issues and planning the total life-cycle of the vessels.

DNV found that fuel costs can account for up to 75 percent of operational costs for container ships. Working with DNV, one major Asian-based container company is said to have achieved annual fuel savings of approximately USD 50 million, and a CO2 emmision reduction of around 300,000 tonnes annually.

**While new technologies and systems are being developed, the real challenges facing shipowners cannot be measured in new technologies or training programmes alone. DNV insists that shipowners must learn to think about energy consumption in a new way.

“Energy Management is not rocket science, it’s change management. The companies we work with know their own ships and their own operations much better than we ever will, but where we contribute are in presenting best-industry-practice, structure and facilitate the fuel-reduction programme and ensure benefit tracking and reporting for continued improved performance", said Cramer.

“But for any Energy Management programme to succeed, it must involve people throughout the organisation working together towards a common objective.”

Whilst Cramer says new regulations and an increasingly uncertain global economy characterised by high fuel costs have encouraged shipowners to be more proactive in managing fuel consumption, he remains somewhat surprised by the industry’s effort so far.

“It is rare in this business that such a small investment cost can yield such big results,” he said. “Optimising fuel efficiency is not only a smart business decision and in line with IMO regulations, it’s the right thing to do.”