|

Avenir LNG begins construction of second 20,000 cbm bunkering vessel in China

Steel cutting ceremony marks start of construction for Hull S1124 at Nantong CIMC facility. |

|

|

|

||

|

Scanocean completes first carbon inset transaction in new environmental service

Bunker seller launches service enabling shipowners to use biofuels while cargo owners purchase emissions reductions. |

|

|

|

||

|

Chimbusco expands bunker trading operations to Greece

Marine fuel trader establishes Greek office with three-person team led by veteran trader. |

|

|

|

||

|

MOL executive calls for development of ammonia bunkering infrastructure

Carbon solution specialist stresses the need to improve ammonia supply chains and safety protocols. |

|

|

|

||

|

Molgas and NorSea Logistics reopen LNG facility in Kristiansund

The reopened facility will supply LNG and bio-LNG to dual-fuel vessels operating in Norwegian waters. |

|

|

|

||

|

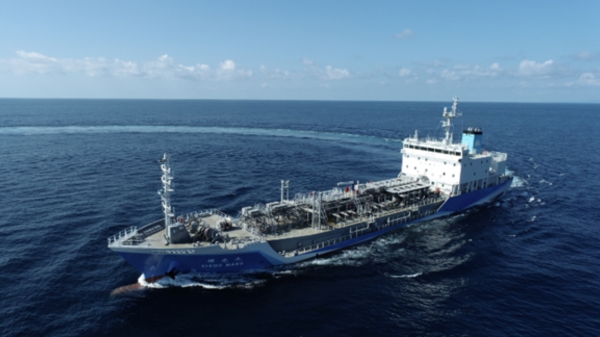

Hydrogen-fuelled tanker achieves top rating in zero-emission programme

Kikou Maru becomes first coastal vessel to secure financing under DBJ-ClassNK decarbonisation initiative. |

|

|

|

||

|

TFG Marine calls for ISO 22192 alignment in ARA MFM rollout

Company urges consistency as Rotterdam and Antwerp prepare mass flow meter implementation. |

|

|

|

||

|

Peninsula renews $400m Singapore credit facility as part of $1.5bn funding capacity

Bunker supplier extends banking arrangement with eight-bank syndicate, including accordion option. |

|

|

|

||

|

Titan delivers first liquefied biomethane to Saint-Malo ferry in Portsmouth

Optimus tanker supplies Brittany Ferries' vessel with biomethane at UK port. |

|

|

|

||

|

MOL outlines ammonia fuel strategy at Houston conference

Japanese shipping company discusses terminal acquisition and dual-fuel vessel plans at industry gathering. |

|

|

|

||

| No upfront payment for fuel-saving retrofits [News & Insights] |

| Option to buy 40 scrubbers in 2015 [News & Insights] |

| VLGC fitted with exhaust gas cleaning system [News & Insights] |

| Scrubber technology for Stena Forerunner [News & Insights] |

| US government grants pollution law exemption to Royal Caribbean [News & Insights] |

| Royal Caribbean to retrofit 19 ships with scrubbers [News & Insights] |